Video measurement system (Abbreviation: VMM) is a new type of high-precision, high-tech measuring instrument integrating optical, mechanical, electrical and computer image technologies.

Video-based measurement systems combine high-resolution images, powerful intuitive software and precision mechanical platforms to deliver superb accuracy and repeatable measurement results for a wide range of precision measurement applications.

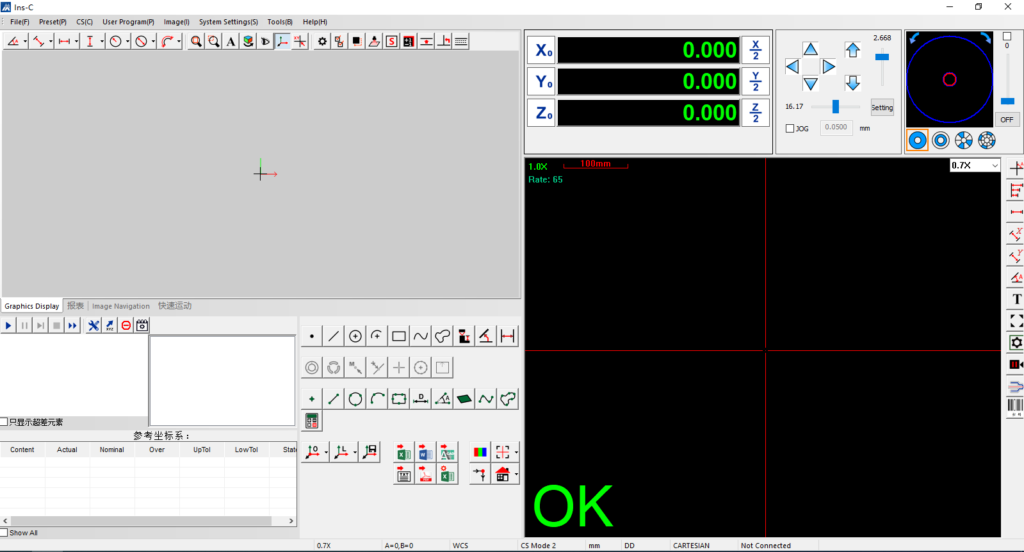

Operating Principle

- High magnification optical image of the measured part is carried out by optical microscope and the magnified image will be sent to the computer by CCD camera system.

- The software will efficiently measure the contour, surface shape, size, angle and position of various complex parts, especially the micro-measurement and quality control of precision parts.

- The measurement data can be directly input into the AUTOCAD to become a complete engineering drawing.

- The graphics can generate DXF documents, and can also be input into WORD and EXCEL for statistical analysis, and a simple Xbar-S control diagram can be drawn to obtain Ca, and other parameters.

We call video measurement system as a VMM, video measurement machine, multisensor measurement machine, image measuring instrument, optical video measuring machine even calls it as optics systems.

Main Components

A video measurement machine is mainly composed of light source system, optical zoom lens, industrial CCD camera control system, measuring software system and precision mechanical platform. The quality of each component and the compatibility of the components affect the accuracy and stability of the video measurement machine.

Measurement Functions

- Measure the linear size, such as point, line, distance, angle, circle, ellipse, rectangle, tangent and the geometrical size, such as straightness, flatness, circularity, cylindricity, perpendicularity, parallelism, angularity, position, concentricity, coaxiality, symmetry, line profile, surface profile, and etc.

- Multi-point measurement to improve measurement accuracy.

- Combined measurement, center point structure, intersection structure, line structure, circle structure, angle structure.

- Coordinate translation and coordinate adjustment to improve measurement efficiency.

- Macro instructions, the batch measurement of the same part is more convenient and quick, and the measurement efficiency is improved.

- The measurement data is directly input into AutoCAD to become a complete engineering drawing.

- The measurement data can be input into Excel or Word for statistical analysis, a simple Xbar-S control chart can be cut out, and various parameters such as Ca can be obtained.

- Customizable output reports conform to customer usage habits.

- Multi-language interface switching.

- Record user programs, edit instructions, and teach execution.

- Fast auto focus, automatic zoom lens.

- Optional contact probe measurement, used for contact measurement of irregular products, such as ellipse, radian, flatness and other dimensions.

- The drawn image can be directly saved as a dxf file, which can be directly opened in autocad software or imported into 3D software.

- Optional touch probe or spot laser to achieve 2.5D and 3D measurement.

Application

Optional touch probe or spot laser to achieve 2.5D and 3D measurement.The instrument is suitable for all application fields for the purpose of two-coordinate measurement, and is widely used in machinery, electronics, instruments, hardware, plastics and other industries. Optional touch probe or spot laser to achieve 2.5D and 3D measurement.