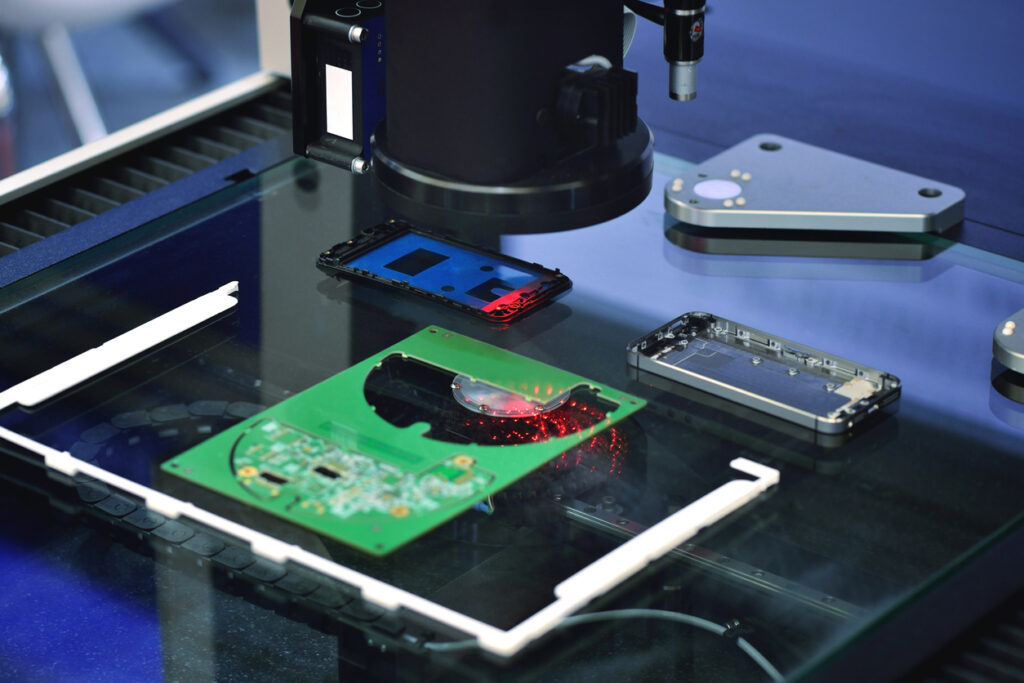

#automatic optical inspection solutions and systems

professional video measuring machine manufacturer

BIG BRANDS' FAVORITE

THEY TRUST US

BYD, BOE and CATL chosen our automatic optical inspection equipment and video measurement system to inspect their well-known product. They were very satisfied with the machine’s high precison and reliability.

Ask For A Quick Quote

Drop Us A Line

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

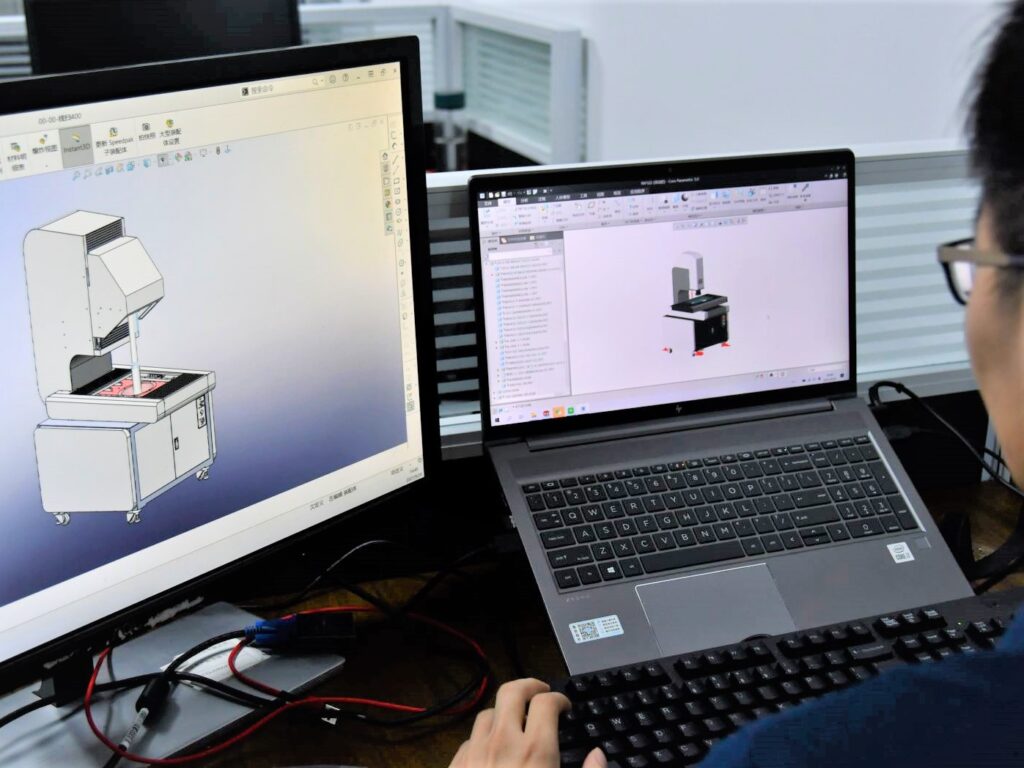

Optics inspection solutions and systems for all inspection tasks

High-precision inspection technologies that inspect external dimensions, surface defects, height, inclination, thickness, etc. fast and reliably are prerequisites for flawless, 100% reliable products. That’s why manufacturers need outstanding technological products for quality control.

XYC-TEK focuses on the research and development of automatic optical inspection equipment and optical core technologies. The products involve pan-semiconductor, integrated circuits, new energy, 3C consumer electronics and other intelligent manufacturing fields.

MEET CHANS VISION AT THE FOLLOWING EVENTS

Display Innovation China Expo 2022

From August 31, 2022 until September 02, 2022. At Shanghai – Shanghai New International Expo Centre(SNIEC), China

International Electronics Circuit Exhibition (Shanghai) 2022

From September 13, 2022 until September 15, 2022. At Shanghai – National Exhibition and Convention Center (NECC), China

Meet your needs

The Optic video measuring machine

XYC-TEK mainly exports standard equipment.

Such as: video measurement system, standard automatic optical inspection equipment, optical modules.

simple and easy

ORDERING FROM US

Newly purchased and delivered video measurement system can be stressful and time-consuming. Importing for video measurement system can be confusing when one is not familiar with the transaction process. Here is a simple process on how to order our machines.

STEP 1

Confirm Measurement & Inspection Solution

It’s important for us to know the measured product and the measurement requirement for your project. But if you don’t, no worries! Our colleagues will help you! Good service is a good beginning of the order.

STEP 2

Sample and production

After Customers pay the deposit, we will arrange the video measurement system production within 1 day. Our approval process is efficient and fast to maximize the time and cost savings for our customers.

STEP 3

Shipping

There are different shipping ways for options. Air shipping is fast but expensive,it’s a good choice for urgent orders, it only takes 7-10 days max. Sea shipping is the most economical shipping way, time is much longer than air, takes 20-30 days.

STEP 4

Installation and Commissioning

Our installation services can help you tackle a variety of projects, whether you’re installing the video measurement system or updating your inspection production line with vision module. Contact us to know more about Chans Vision’s products and services for your project.

STEP 5

After-sales Service

At every stage of an end-of-line machinery project, our customer service department will be there for you. Our team is available to assist you with day-to-day tasks such as machine installation, spare parts delivery, commissioning, and maintenance.

Our experts are easy to reach, responsive, and enthusiastic about their work, so you can rest assured that you will be satisfied!

For a worry-free project, contact us today!

PROTECT YOUR MONEY

THE COMMON PITFALL WHEN PURCHASING

There are different things to consider when ordering any product, including video measurement system from China. There are many great machines out there.

However, some suppliers offer low-quality machines that need to be avoided. It is vital to make sure that you are getting the right machine. You need to take some steps to ensure that you are not being cheated by fake sellers.

Take the example of buying a video measurement system:

- Choose a well-known company and check the online reviews.

- See what clients they're cooperating with.

- On-site visits are possible.

- With professional and reliable component suppliers for their equipment.

- After-sales details need to be thorough.

- Timely delivery.

The purpose of buying video measurement system and learning the technology of video measurement system production is, in the end, to make good, high-quality products. And the outcome is recognized by the market. Thus, your business can achieve good economic benefits.

So companies buying video measurement system equipment must choose a reliable supplier to work with to ensure that your video measurement system business can succeed. The supplier is to provide reliable quality system, timely after-sales service, solutions to problems encountered in the production process, and advice and support in market development.

A manufacturer that can provide integrated services is the most reliable partner to build your video measurement system business.

Let XYC-TEK Save Your Time & Cost

The Choice of People

Why choose XYC-TEK

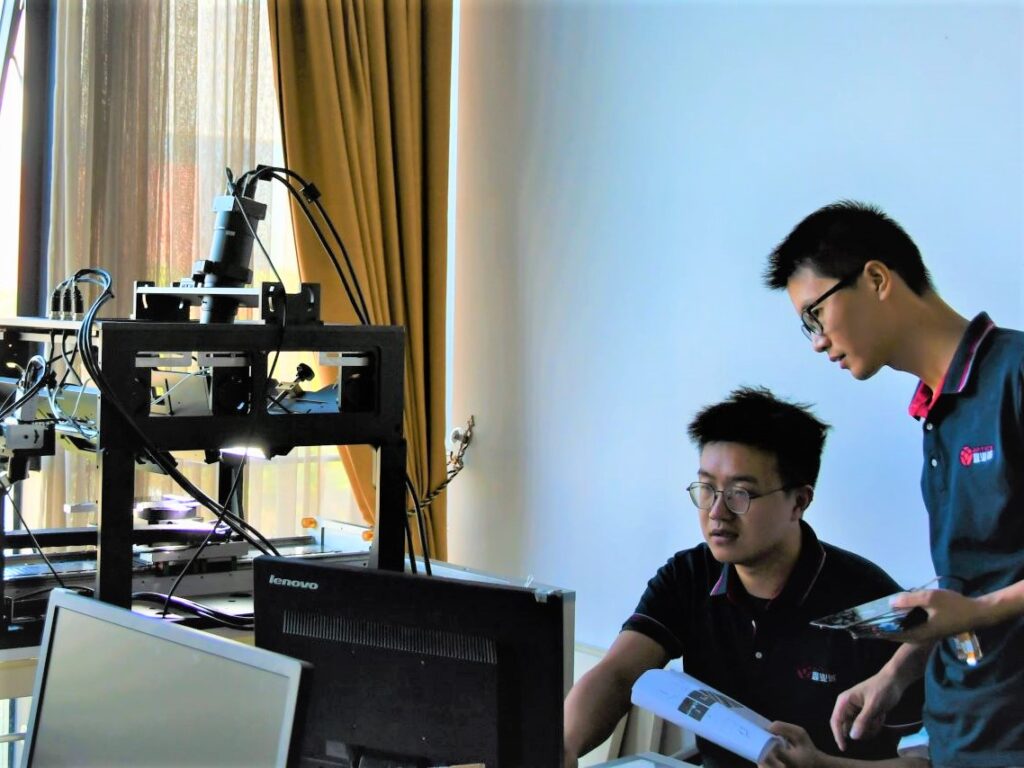

XYC-TEK is the provider of automatic optical inspection solution and system for many manufacturing industries through its innovative product and software design.

Our main products are video measurement systems, AOI machines, semiconductor inspection & processing and customized inspection solutions.

Inspection is an essential technology in all manufacturing sectors around the world. XYC-TEK systems are used by manufacturers to measure and inspect their products for quality and process control.

- 6 Years of Experience

- Customized Inspection Solutions

- Full-value Service and Support

- 24/7 Availability

270+

Own Patents

228+

Happy Customers

30%

R&D Expenses

6

Years In Service

OVER 6 YEARS FOR ONE GOAL - FOCUS ON THE DEVELOPMENT AND MANUFACTURING OF INSPECTION SOLUTION

We specializes in the development and manufacture of video measurement systems, AOI machines, semiconductor inspection & processing and customized inspection solutions. For over 6 years development, excellent quality and professional service bring us stable customers from all over the world.

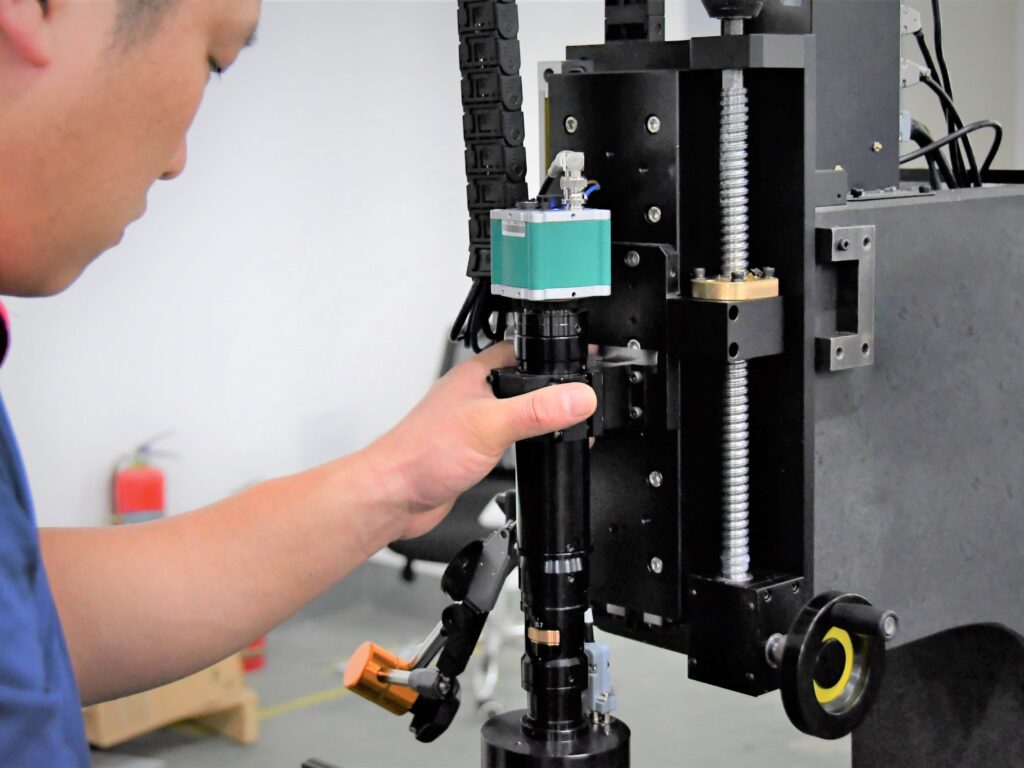

HIGH QUALITY VIDEO MASUREMENT SYSTEM START FROM THE BASICS

Production team adopts ERP system to manage the engineers and workers and plan the enterprise resource. From raw material procurement to production, quality inspection has a perfect management system.

COST SAVINGS OF 10% - 20 %

For customers to save cost, improve work efficiency, professional tracking product quality and after-sales service, establish efficient service system. High speed, high quality, high precision, high cost-effective, up to 10% – 20% cost savings.

CARING SERVICE 24/7 ONE-TO-ONE SERVICE FOR YOU

Professional logistics and distribution, to ensure the equipment with accurate delivery in time.

Professional technical personnel to provide you with staff training and technical services and support with free of charge.

Professional after-sale team regularly visit by internet or on-site, rapid response within 24 hours.

Top Questions You May Ask

You need our system as long as one of the following is met:

- The factory produces a large number of products, and each product needs to be tested for size, appearance or defects.

- The output of products produced by the factory is small, but it involves the strict detection of product size, appearance or defects, and the manual detection method can not meet the requirements.

- Although the product can be tested manually, the efficiency is low or the misjudgment rate is high.

- High local labor cost or lack of labor force.

Since its establishment in 2016, Chans Vision has focused on the field of visual inspection. It has also established a professional R & D department and production team. We have become a supplier to international enterprises such as BIEL, INTERFLEX, BOE, BYD and CATL and top enterprises in China. We regard the reputation and quality as our core values. Believing that we will grow stronger at a higher speed in the future.

We can design the machines according your requirements (our brand, OEM, ODM),at the same time we will give you our professional suggestion, as you know, we have been in this industry for many years.

We have no sample. We will send you more pictures and video about this machine. Surely can help you do the inspection for samples and welcome to visit our factory to see the machine running in the factory.

We will provide free training to the machine operators in our company, until they can understand the equipment structure technical principle proficiently and can correctly programming, operating, inspecting, maintaining and caring the equipment.

The customer can send the engineer to our company to complete the inspection of the goods, as well as the installation and training lessons. Or we will send the engineers to install and have training lessons abroad.

For every customer, we offer all-day response service. Customers’ equipment use problems and maintenance problems will be guided and solved by phone call or video call at the first time, or solved on-site through local agents and service teams. In addition, we will send the after-sales service team of the factory to visit and make the technical communication with customers in various countries from time to time to ensure that our products can help our customers obtain the maximum benefits.

We welcome agents from all over the world to join us. For overseas agents, we will regularly or irregularly send overseas sales and after-sales service teams to visit as needed to assist agents to visit customers and carry out technical communication. At the same time, our agent team will receive corresponding technical and after-sales service training, cooperate with us to participate in relevant local exhibitions, or invite overseas agents to visit Chinese factory.