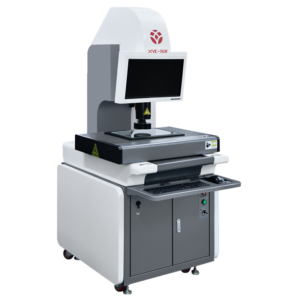

Equipment principle and purpose

Working principle of the equipment:Through the principle of opticalmetallographic image magnification, the product is subjected to highmagnification microscopic inspection, and the product results are analyzed andjudged. The equipment has a high-resolution color camera to improve its videoanalysis and measurement performance; it makes measurement simple andfully utilizes the measurement hardware performance of 3D spatial functions.It combines an easy-to-use user interface and powerful software computingcapabilities to bring reliable Z-axis precise measurement output andperformance.

Equipment use:High-power 3D image inspection instruments are widely usedin high-precision inspection industries such as semiconductor chips, packaging,LCD circuit boards, magnetic materials, and printed circuit boards (circuitboards, PCBs).

Technical Parameter

| Model | XWG200-CNC | XWG300-CNC |

| XYZ Measure range(mm) | 200*200*150mm | 300X200X150 |

| Dimension(mm) | 767*1093*1520 | 970x1490x1520 |

| Glass table size(mm) | 270*270 | 370X370 |

| Machine Weight(kg) | 260 | 300 |

| Max Load(kg) | 25 | |

| Optical magnification | 6-50X | |

| Video magnification(24 inch display) | 332X-2770X | |

| XZ axis measure accuracy(um) | 1.8+L/250 | |

| XY repeatability(um) | 1.8 | |

| Z axis accuracy(um) | 2.5+L/250 | |

| Z repeatability (um) | 3 | |

| Machine move speed | XY axis:100mm/S Z axis:20mm/S | |

| Environment requirement | Temperature 20±2 ℃,Humidity ≦2℃/hr | |

| Power supply | AC220-240V、50Hz、1200W | |

Machine configuration

| Item | Name | Part | Specification |

| 1 | Machine

Host |

Mechanical structure | granite main structure, small expansion coefficient, stable physical properties |

| 2 | Working table | Cast iron material, stable physical properties | |

| 3 | Linear scale | Germany“RSF”0.1um metal scale | |

| 4 | Guideway | Cross Roller Guides | |

| 5 | Screw | Taiwan TBI ball screw | |

| 6 | Optical system | Camera | 2/3 inch 5M pixel digital color CCD(USB3.0) |

| 7 | Optical Lens | 0.6-5.0X auto lens with coaxial light +

10X Olympus long working distance objective |

|

| 8 | Video magnification | 332X- 2770X (24 inch display) | |

| 9 | View field

(without 10X olympus) |

12.3*9.3mm(0.6X)-1.5*1.1mm(5.0X) | |

| 10 | Transmitted light | Spherical integral parallel light path LED transmission light source (255 levels arbitrarily adjustable) | |

| 11 | Coaxial light | LED cold light source(white light)(5V 10W) | |

| 12 | Electronic control system

|

Controller | XW-300 |

| 13 | 3 axis motor | Japan “Panasonic” high-performance AC servo motor (drive closed loop) | |

| 14 | Joystick | XW-A | |

| 15 | Software | Measure software | PolyGaugeFully automatic metallographic measurement software |

| 16 | PC | Pc host | Lenovo I5-12 generation CPU, 256G hard drive, 16G memory, 4G independent graphics card, 24-inch monitor |

| 17 | Accessory | Calibration block | Photolithography standard element calibration block |

| 18 | Factory certificate | Factory certificate | |

| 19 | Factory inspection report | XW factory inspection report | |

| 20 | Hardware manual | Hardware manual, software manual | |

| 21 | Optional | Metallographic lens | 5X、20X、50X |

Chans Vision’s Engineers are inspection specialists, qualified to evaluate your measurement requirements and recommend the solution that best fits your needs.

Your profesional service team is ready to help you with product details, demonstrations, training, or purchase information.